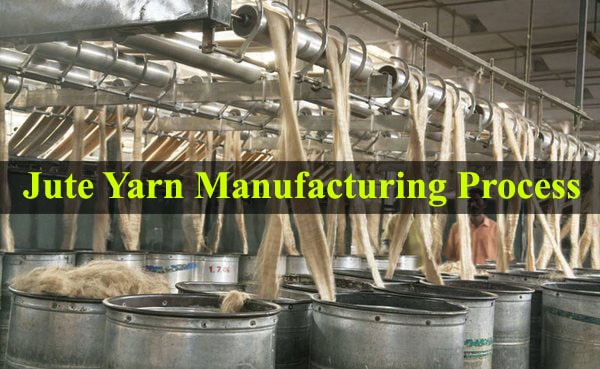

Welcome to the fascinating world of jute yarn manufacturing process, where old customs meet cutting-edge technology to create one of the world’s most useful and long-lasting fibers. The steps used to make jute yarn are carefully planned out and turn raw jute fibers into strong, long-lasting, and eco-friendly yarns. That being said, let’s start our trip through the complicated and long-lasting process that gives this amazing natural material life. Discover the secrets of how jute yarn is made as we look into its long past, eco-friendly uses, and the cutting-edge methods that make it an important part of the textile industry today.

Jute, which is sometimes called “golden fiber,” is a natural material that has been used for hundreds of years in many fields. It is eco-friendly and can be used in many ways. Making jute yarn is one of the most popular uses of jute. This yarn is the base for many different products, such as textiles, bags, carpets, and more. We will learn a lot about the fascinating process of making jute yarn in this piece, from the raw jute fibers to the finished spools of yarn.

Where to look Jute

Jute is one of the most important natural goods in terms of how it is grown and how it is used. Things that can be grown rely on the land, the season, and the weather.

The Ganges Delta is where almost 85% of the world’s jute is grown. This beautiful land is shared by India and Bangladesh, mostly West Bengal. China also grows a lot of jute. Small amounts of jute are grown in Thailand, Myanmar (Burma), Pakistan, Nepal, and Bhutan.

Jute Yarn Manufacturing Process

Starting with growing jute plants and ending with making the yarn is a long process that is used to make jute yarn. Jute is a natural fiber that is mostly grown in warm places like India and Bangladesh in the summer. Here is a summary of the steps used to make jute yarn:

How to Grow Jute:

- Jute plants are grown in rich, well-drained soil during the monsoon season.

- The plants need to be watered often and will be fully grown in 4 to 6 months.

- The jute plants are usually picked when they are fully bloomed.

Retting:

- The jute stems are bundled up and put in bodies of water (ponds, rivers, or tanks) for a few days to a few weeks after they are picked. Retting is the name for this process.

- Some bacteria and germs break down the pectin that holds the jute fibers to the stem during the retting process. This makes it easy to separate the stuff that doesn’t have fibers from the stuff that does.

Stripping and Separating:

- The jute stems are taken out of the water and left to dry in the sun after retting.

- After it dries, the non-fibrous material on the outside is taken off of the jute fibers. Often, this is done by hand or with the help of tools.

Fiber Bundling:

- Next, the jute fibers are grouped together to make raw jute bundles.

Carding:

- This is the process of combining the jute fibers to line them up in a straight line. These changes make the yarn better. In this case, carding tools are used.

Spinning:

- To make jute rope, the carded jute fibers are put into machines that spin them. These machines twist the fibers together.

- Some types of spinning tools can be used to make yarn of different thicknesses and qualities.

Drying:

- Jute yarn that has just been spun is generally wet and needs to be dried. This can be done by putting the items in the sun or using dryers.

Quality Control:

- The jute yarn is checked for flaws and differences in quality and thickness.

Packing:

- The jute yarn is put into spools, hanks, or boxes after it has been checked for quality. It is then ready to be sent out and processed further.

In conclusion

It is important to keep in mind that the process of making jute yarn can be slightly different, and that different mills may use slightly different tools and methods. Different types of jute yarn have different qualities depending on things like the jute fibers used, the retting process, and the skill of the workers who make the yarn. Many things are made from jute yarn because it is natural and good for the environment. Some examples are textiles, rugs, bags, and more.

The path of the Jute Yarn Manufacturing Process is amazing. It starts with raw jute fibers and ends with a versatile material that can be used in many ways. Every step in the process of making this eco-friendly and long-lasting product is important. From the farms where the jute plants are grown to the specialized machines used for extraction, carding, spinning, and quality control, everything plays a part. People are looking for eco-friendly and biodegradable choices more and more, and jute yarn is still a beautiful example of a natural fiber that people love.